Machining is a generic term for various manufacturing processes such as milling or turning used to give workpieces a specific shape by removing excess material via mechanical influences.

According to the wishes of our customers, we can realise high surface qualities with sealing surfaces as well as a dimensional accuracy of 10 μm.

Machining can be used on a variety of different materials:

- Stainless steel

- Non-ferrous metals

- Nickel-based materials

- Titanium materials

- Plastics

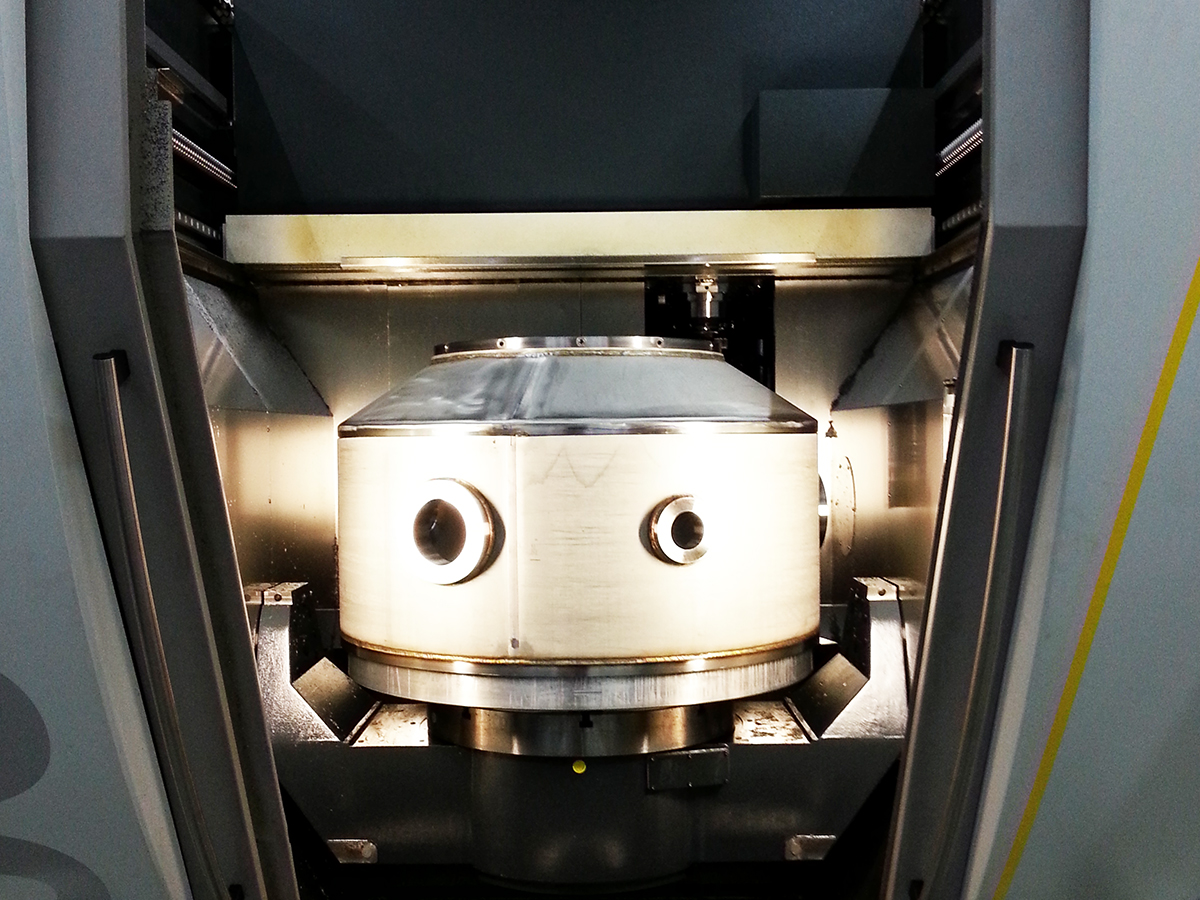

Alzmetall GS 1400 5T

Traverse path: 1250 x 1250 x 870 A axle ± 140° C – axle 360° (endless)

- High precision machining centre in gantry construction

- All axles are double-equipped with motor and linear scales

- Rotary axles are driven by torque motors

- Zero point clamping system

Alzmetall GS 1000 5

Traverse path: 800 x 900 x 600 A axle ± 140° C – axle 360° (endless)

- High precision machining centre in gantry construction

- All axles are double-equipped with motor and linear scales

- Zero point clamping system

CMZ TL 225 T M

Turning diameter over bed: 685 mm turning diameter over plan support: 510 mm

Rotatable maximum diameter: 400 mm tip distance: 526 mm

Traverse path: Z axis: 640 mm X axis: 240 mm

- Driven tools

- Polygon – recordings for fast conversion

- Tailstock

The advantages of machining processes are in particular the very high accuracies and surface qualities. Feel free to contact us if you have further questions about our service portfolio and various individual application options.

Deutsch

Deutsch